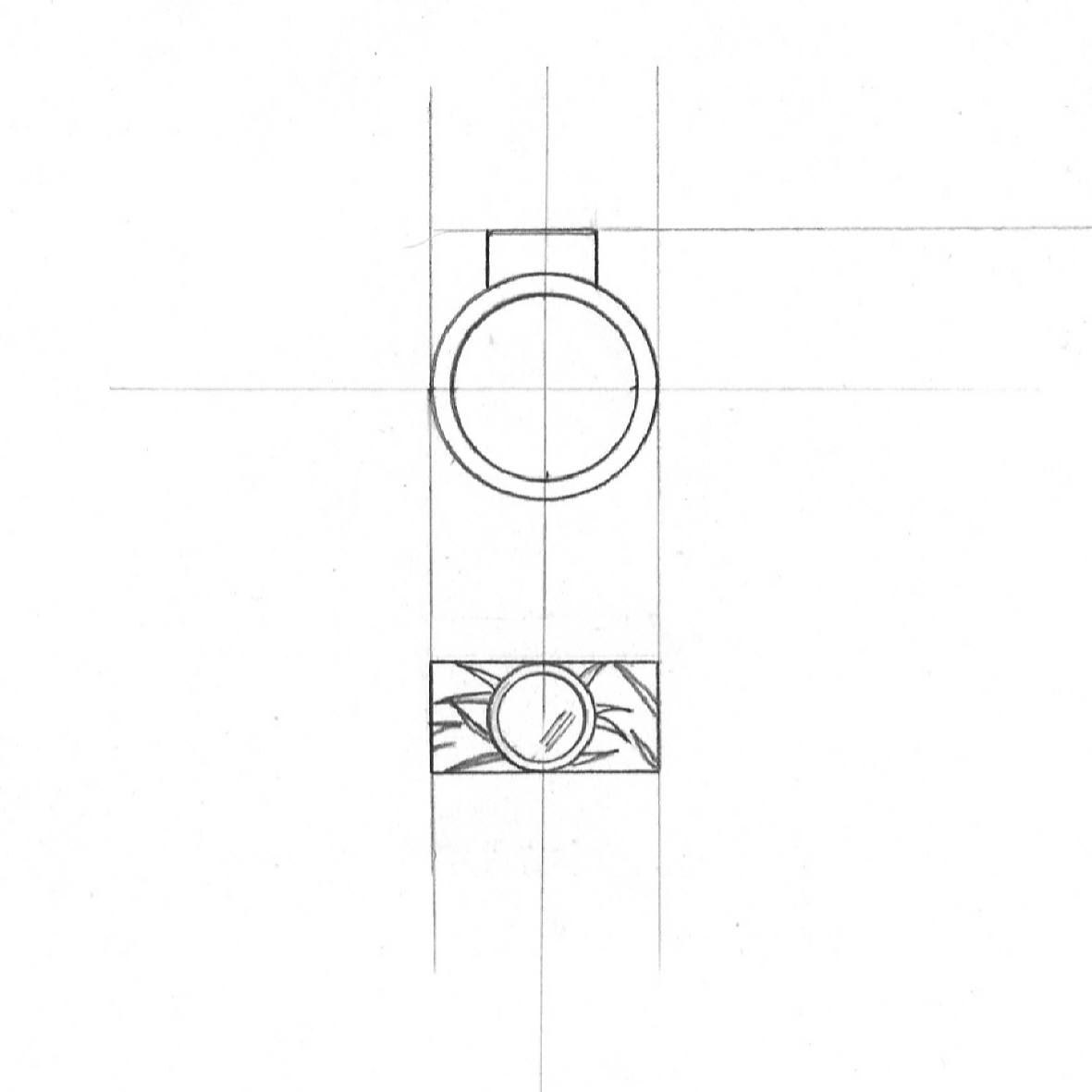

Step 1 Here follows how to make a ring with a stone just like the one in the picture above.

The ring is made by following these steps:

The ring is made by following these steps:éPüjMake the bezel for the stone

éQüjCreate the ring

éRüjSolder the ring and the bezel

éSüjSet the stone

éTüjFinishing, polishing.

Step 2 Consider how much silver material you will need

|

The Formula to follow "L" is the length you need to make the ring the circumference is"d" "L"üüü@â╬("d"+t)= S+tâ╬ "t":thickness of the silver "S":European size |

thick silver sheet, Length of ring (L)üü52+1.8â╬=57.65

When the width is 12mm, the silver weight will be about xxg.

In addition, for the 0.5mm thick bezel, you will need silver as follows,

CarnelianüFdiamiter(d):11.5mmü@height:5mm

length of bezel (l)üüâ╬(d+t)=3.14(11.5+0.5)=37.68

It will weigh yyg and the ring will need zzg silver totally.

At the 'Studio Ring' we ask participants to pay for the material, JPY 90 per 1g.

The material fee may change according to the market price.

Step 3 Let's make the bezel.

Step éSü@Lets' make a ring

Step éTü@Let's set the stone.

Solder the bezel and the ring.